The sustainable use of essential material resources is an increasing global priority as technology intensive sectors such as large-scale data infrastructure, electric mobility, and renewable energy systems expand worldwide. This fact has been previously researched by several studies. The environmental impacts of raw material consumption across industries, highlighting the urgency of improving resource efficiency [1]; The supply risks for strategic minerals, linking them to geopolitical dependencies and price volatility [2]; The material flows in renewable energy technologies, identifying bottlenecks related to critical elements [3]; The lifecycle impacts of high tech products, demonstrating the potential of design stage interventions to reduce material intensity [4]; Outlining sector specific efficiency strategies and tracking global trends in resource demand growth [5], [6] or quantifying the vulnerability of renewable energy technologies to critical raw material supply chain disruptions [7].

Materials essential to the economy and whose supply may be at some risk are known as critical materials. From the perspective of the state of the art related to critical materials, the reports published by the European Commission stand out. Since 2010, five updates have been presented. The latest was published in 2023 and included up to 34 critical and strategic materials for Europe [8].

The main conclusion that can be drawn from this report is that the dependence on critical materials continues to grow, as evidenced by the increase in the list of critical materials from 14 in 2010 to the current 34. The current list highlights the presence of light rare earth elements (LREEs) and heavy rare earth elements (HREEs), semiconductors and electronic components (Ge, Ga, Ta) and platinum group metals (PGMs), metals essential for manufacturing high-strength alloys (Cr, Nb, Sc, Ti, V, W), and materials for battery construction (Co, Mn, Li). Finally, it is notable, and concerning that, this list includes elements as basic and fundamental to the economy as copper, nickel, magnesium, and aluminium.

The concentration of the production of these materials in a limited number of countries and potential changes in foreign policy increases the risk of sudden interruptions and, therefore, strategic exposure. To address this vulnerability, it is evident that circular economy measures need to be promoted to encourage the efficient use of critical materials. In this regard, it is essential to note that although circular economy policies have been developed for several years, much remains to be done as the functional recycling rates for most critical metals are still practically non-existent [9].

For all the reasons mentioned above, it can be asserted that technologies increasingly require a greater diversity of materials for their manufacturing, many of which are scarce at a geological level. Furthermore, despite being abundant, many materials have such high demand, low recyclability, and concentrated supply in a few regions that they are equally considered critical [5], [10].

Many studies have analysed the dependence of various technologies on critical materials. Notable among them are those focused on technologies necessary for the carbon-free energy transition, such as renewable energies and electric mobility.

Previous research has largely focused on critical materials in specific clean energy technologies. Santini et al. [11] analysed photovoltaic supply chains for bottlenecks involving tellurium and indium. Dalhamar et al. [12] evaluated cobalt and lithium availability for electric mobility systems. Pigosso et al. [13] modelled long term supply ‒ demand dynamics for minerals essential to the energy transition, highlighting the role of recycling and substitution. However, there is a lack of systematic analysis addressing the criticality of materials in container based, self-sufficient habitable modules ‒ a gap this work seeks to fill.

Eco design has emerged as a cornerstone strategy to address this challenge. It aims to extend product lifespan, enable disassembly for efficient recovery of critical metals, and promote substitution with more sustainable alternatives. Bundgaard et al. [14] developed a framework for implementing eco design principles in industrial product development, achieving measurable reductions in material intensity. Luttropp et al. [15] demonstrated how disassembly-oriented design improves recovery rates for critical metals in electronics. Ortego et al. explored substitution pathways in energy technologies, maintaining performance while reducing supply risk [16] and quantified the lifecycle benefits of eco design interventions, showing both environmental and strategic gains [17]. Popescu et al. [18] emerging sustainable materials and advanced recycling technologies can complement eco design strategies, further reducing environmental impact and criticality. These principles are directly applicable to modular construction, where they can enhance sustainability and resilience.

In this context, this paper presents an assessment of resource efficiency from a materials perspective, applied to habitable modules based on containers. This studyses the thermodynamic rarity-based approach [19], which is used for the first time in an energy-self-sufficient habitable module designed for defence purposes. This will serve as a starting point, aiming to eco-design defence equipment to be more environmentally sustainable and resilient to Europe's dependence on critical materials. This research aligns directly with United Nations Sustainable Development Goal 7 (Affordable and Clean Energy), Goal 9 (Industry, Innovation and Infrastructure), and Goal 12 (Responsible Consumption and Production), by proposing material efficient, self-sufficient modular designs that reduce reliance on critical resources while maintaining performance.

Applying thermodynamic rarity indicators to guide material selection can significantly reduce reliance on scarce resources without compromising technical performance. This will serve to response the following questions: Which subsystems contribute most to overall material criticality in the studied module? How do alternative energy storage technologies affect thermodynamic rarity outcomes? And which eco design measures can be implemented to lower critical material use while maintaining functionality and aligning with relevant United Nations Sustainable Development Goals?

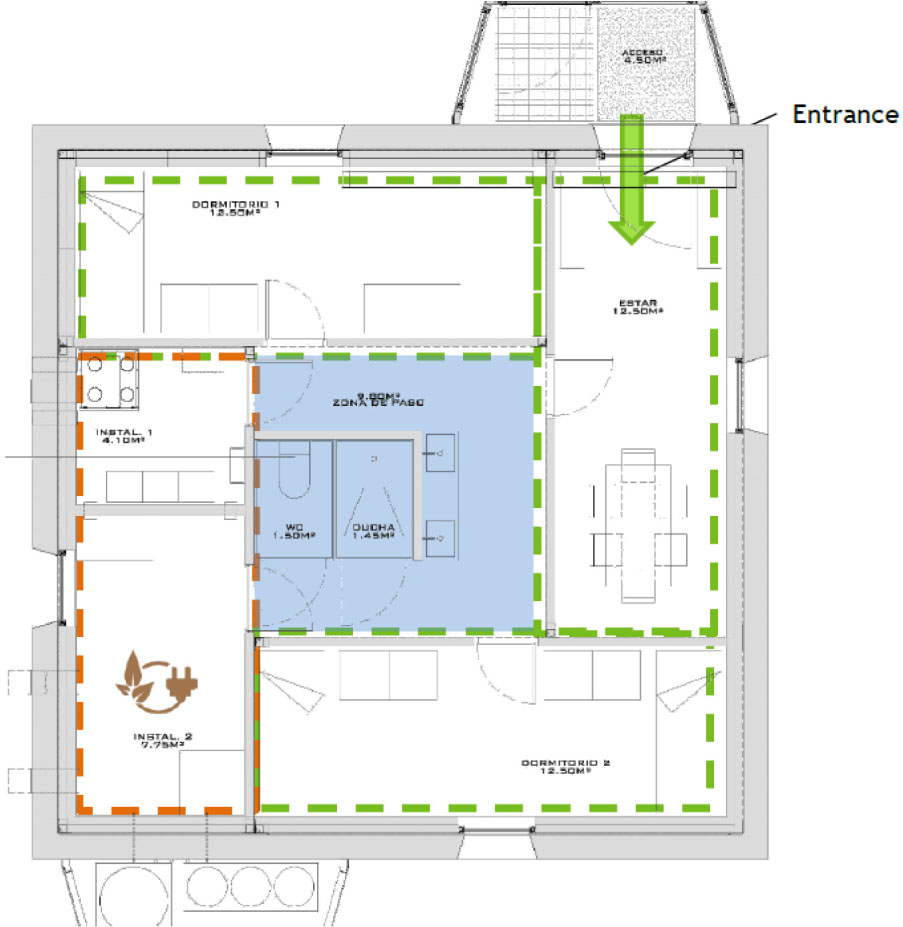

The case study is the demonstrator built as part of the ZEROENERGYMOD project financed by the LIFE program [20]. In this project, a habitable, demountable and modular module has been designed and built from 20-foot containers. Figure 1 presents the floor view of the module.

Floor view of ZEROENERGYMOD demonstrator

The module is built from the union of 4 containers of 20 feet each one. This configuration offers a total useful surface area of 70.5 m2, of which 43.2 m2 are rooms, 14.4 m2 is the facilities room, and 12.9 m2 is the central area with the toilets. The containers have a rigid stackable chassis structure, modified from those currently available to avoid thermal bridges. The base insulation of the removable panels of the chassis is 10 cm of high-density wool and double tongue and groove. On the inside, there is another layer of the same panels, and on the outside, there are 30 cm thick skins of high-density wool with a stainless-steel exterior finish.

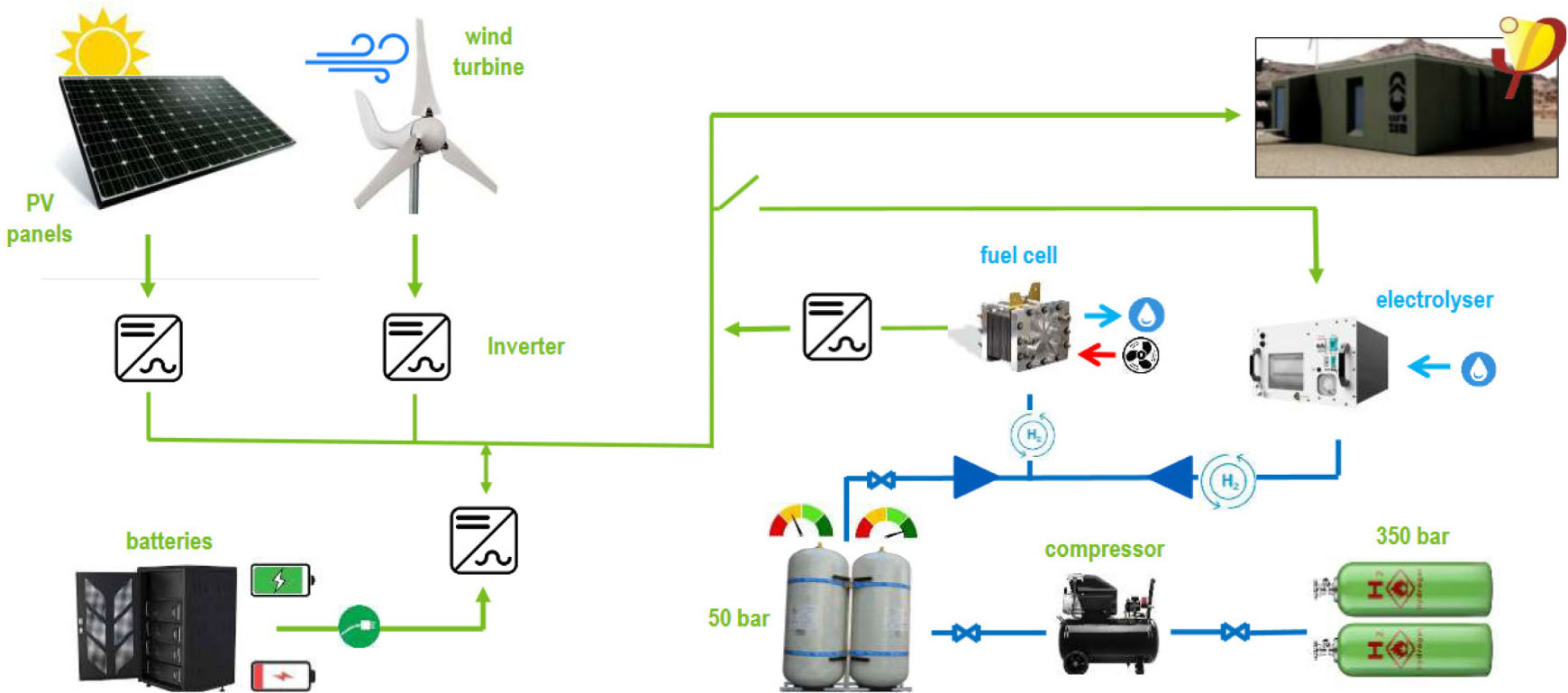

Since this construction is designed to operate in remote areas in an energy self-sufficient way, it has its own power generation system using solar photovoltaic modules (5.4 kWp) and small wind turbine (3 kW). In addition, lithium-ion batteries (LiFePO4 with 14.4 kWh) and a hydrogen generation, storage and use system are available for energy storage. It is also highlighted that a controlled mechanical ventilation system provides air conditioning with enthalpy recovery powered by aerothermal energy.

Finally, it must be noted that the module requires 90% less energy than existing modules, thanks to the high level of thermal insulation of Passivhaus standards. It is self-sufficient, as the module generates and stores the little energy it needs to operate. Figure 2 shows the scheme of the energy systems.

Scheme of energy systems

The demonstrator has already been built and is operating at the earth´s army facilities in Zaragoza (Spain) (see Figure 3). The module is being tested in this location, and adjustments are being made to the energy management systems. The module will be moved to the Spanish army base in Antarctica where its operation under extreme weather conditions will also be tested.

Current state of ZEROENERGYMOD in its location in Zaragoza (Spain)

It is essential to point out that the application of the module is valid beyond the defence sector. This system is helpful for any need where it is necessary to install a fast, energy-efficient housing solution. Therefore, schools, temporary hospitals or housing in areas affected by natural disasters are perfect applications for this construction solution.

Their material composition is first assessed to calculate the criticality of the components. In this sense, the metals used in the main components of the habitable module are analysed. The analysis excludes plastics, polymers or fibres that may be used in construction elements.

Given that the objective is to analyse the criticality of the singular components of ZEROENERGYMOD in order to propose eco-design measures, the following components are considered as study components: Solar photovoltaic installation; Small wind turbine; Batteries, Fuel cell; Electrolyser; Self-supporting structure and Internal partitions.

The selection of these elements is based on the fact that they have been identified as emerging technologies by the European Commission, and at the same time, their future development may be conditioned by the sufficiency of material resources [21]. On the other hand, construction materials like sandwich panels used in the structure are analysed due to their high contribution to the total weight of the module.

The methodology was designed to align with SDG 7, SDG 9, and SDG 12 by quantifying material efficiency in off-grid renewable systems, comparing alternative energy storage technologies, and identifying eco-design measures to reduce critical raw material dependence. This alignment ensures that the assessment framework directly addresses global targets for clean energy, sustainable industry, and responsible consumption.

Ortego et al. [22] demonstrated that assessing the metal demand of a complex product based on mass alone does not incentivise the recycling of minor metals, such as Rare Earth Elements (REE), semiconductors, or alloying elements. To address this issue, an alternative method was proposed grounded in the second law of thermodynamics and the concept of exergy. This method introduces an indicator known as thermodynamic rarity (or simply rarity), which assigns a physical value to minerals based on two key parameters: (1) their relative abundance in nature and (2) the net energy required to extract and refine them.

By applying this indicator, valuable metals like those in the platinum group or refractory metals are found to be orders of magnitude rarer than common metals like iron or aluminum. This indicator is purely based on the physical properties of the commodity, making it universal, objective, and more stable compared to monetary-based approaches.

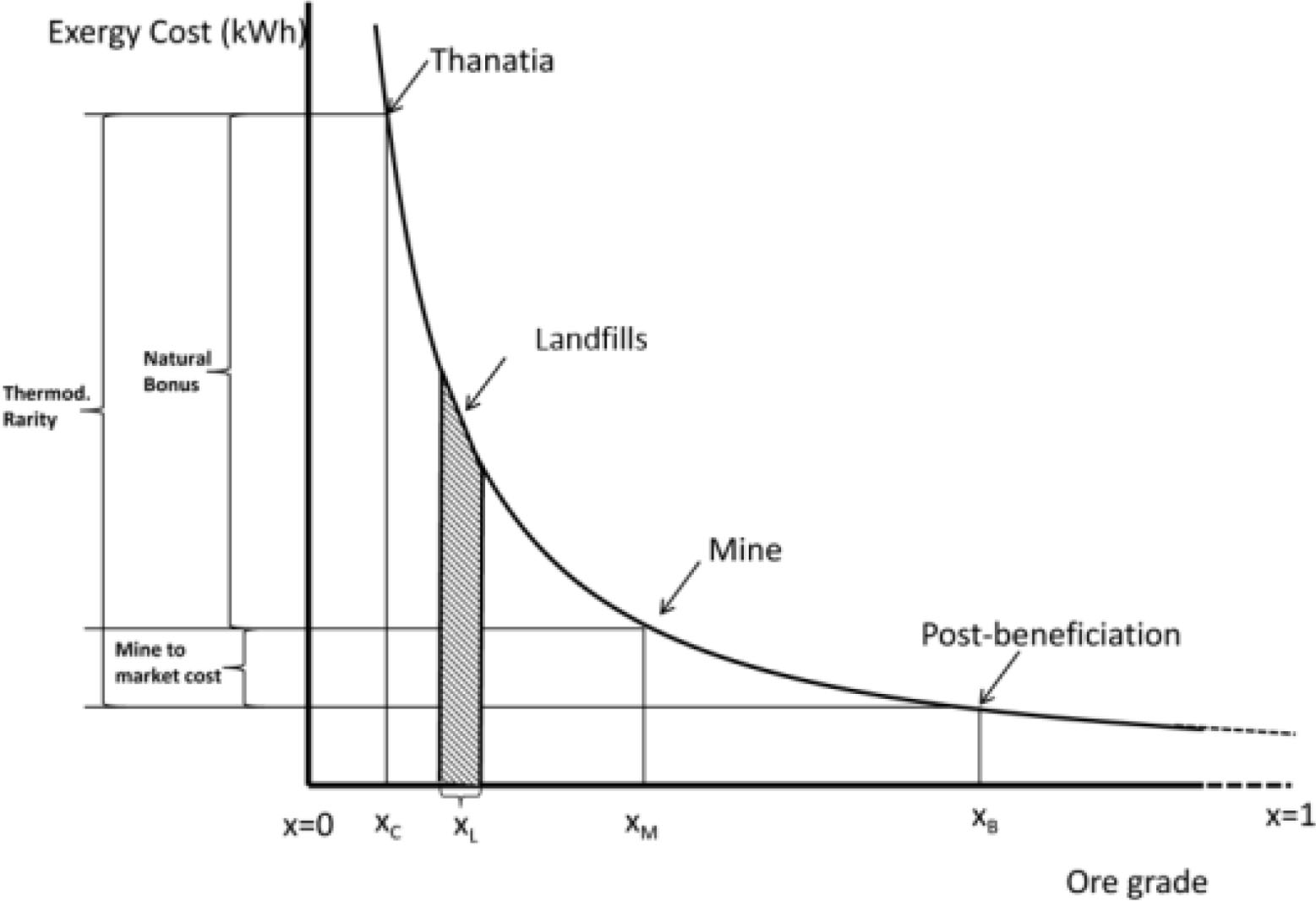

It’s essential to first discuss metal production to understand how rarity is calculated. The primary production of metals relies on mineral deposits dispersed throughout the Earth's crust, and the physical value of mined minerals largely depends on their inherent chemical properties and concentration relative to the Earth's crust ‒ essentially, their scarcity. A highly concentrated mineral ore is rare in its surroundings and possesses significant exergy, leading to lower energy costs for extraction. Conversely, as resources become scarcer, extraction costs increase exponentially as ore grades diminish [23]. Therefore, two critical factors in mineral resource assessment are captured through thermodynamic rarity: the exergy cost (kJ) required to extract and refine minerals and the natural advantage provided by concentrated mineral deposits, termed exergy replacement costs. Both the "cradle to gate" and "grave to cradle" approaches are vital, as the former emphasises efficiency ‒ indicating that reducing embodied exergies can lead to cost-effectiveness ‒ while the latter highlights conservation by advocating for preserving valuable and scarce minerals through exergy replacement costs.

Thermodynamic rarity is calculated as the sum of exergy replacement costs and embodied exergy costs (see Figure 4). Assuming no technological changes, rarity remains constant. Historically, mineral deposits were abundant and highly concentrated (resulting in high natural bonuses and low exergy replacement costs), making mining and beneficiation relatively easy with low embodied exergy costs. However, as the most accessible resources have been exploited, the industry now faces the challenge of mining lower-grade ores, requiring more profound and, consequently, more energy-intensive efforts (thus decreasing the natural bonus and increasing embodied exergies). In some instances, technological advancements can partially mitigate the effects of declining ore grades [24]. Thermodynamic rarity, therefore, represents the exergy resources required to obtain a mineral commodity from ordinary rock using current technology.

Thermodynamic rarity represents the exergy cost (kWh) needed for producing a given mineral commodity from bare rock to market, i.e., from Thanatia to the mine and then to post beneficiation. Source Valero and Valero [19]

Rarity measures in energy terms, the impact of using those raw materials in any application, considering the state of mineral ores in the earth and mining and beneficiation energies. Thermodynamic rarity values for the 24 metals analysed in this study are included in Appendix A. Such values are used as weighting factors for each metal used in the habitable module to identify the most critical components, and from there, eco-design recommendations can be easily derived.

This method was defined by Valero A. and Valero A. [19] and its effectiveness in measuring resource efficiency has been tested with other products such as laptops, smartphones or vehicles [25], [26], [27].

To apply this thermodynamic approach, it was necessary to calculate the criticality of the main components, such as solar installation, fuel cell, or module envelopes. The criticality is calculated by using the thermodynamic rarity [kJ]. To assess the thermodynamic rarity of each component, it is necessary to have the metal composition for each one. To do it, a table (see Table 1) was built in which the quantity of each studied metal for each component is represented.

Example of the table to make the thermodynamic assessment

Metal 1 |

..... |

Metal n |

|

|---|---|---|---|

Component 1 |

|||

..... |

|||

Component n |

Data from the metal composition of each component come from manufacturers' datasheet or by reviewing scientific literature. Once this table is built, the thermodynamic rarity assessment is made by multiplying the weight of each metal by the thermodynamic rarity value of each metal. In eq. (1) is presented the method. Where A is a component, m is the mass in [g], Rarity is expressed in [kJ/g] and i is the studied metal:

Eco-design measures are proposed based on identifying the most critical components and the metals responsible for this criticality.

The results are presented below, organized by section. Given that one of the main results is material composition, the first section includes this information. This is followed by the criticality assessment based on the thermodynamic approach and, finally, the eco-design proposals.

The study components of the module are listed in Table 2.

Equipment list of the main studied components

Component |

Description |

Quantity |

|---|---|---|

Solar PV installation |

Solar PV modules. Monocrystalline. Pmax 450 W. |

12 units |

Small wind turbine |

Output AC. 3000 W. |

1 unit |

Batteries |

LiFePO4. Capacity 3.6 kWh/ud. |

4 units |

Electrolyser |

H2 production 1.07 kg/24 h. H2 production at 35 bar max. |

1 unit |

Fuel cell |

DC voltage 48 V. Power 2500 W. Fuel cell type PEMFC. |

1 unit |

Self-supporting structure |

Sandwich panel: Out face (Stainless steel with 2 mm of thickness) Inner face (Painted steel with 2 mm of thickness). Internal insulation with high density wool. |

94.08 m2 |

Internal partitions |

Sandwich panel: Faces (Painted steel with 2 mm of thickness). Internal insulation with PUR. |

14.4 m2 |

From this table, using both manufacturer’s data sheets and scientific literature, the list of the main materials for each component was compiled (see Table 3). For each component metals are ordered by their mass contribution.

Metal composition of each component

Component |

Metal |

Mass (kg) |

Source |

|---|---|---|---|

Self-supporting structure |

Fe |

1,930.2064 |

manufacturer datasheet |

Cr |

423.0589 |

||

Mn |

52.8824 |

||

Ni |

237.9707 |

||

Internal partitions |

Fe |

2,746.1489 |

manufacturer datasheet |

Mn |

53.3505 |

||

Mo |

8.4238 |

||

Solar PV installation |

Cu |

22.5585 |

metal composition for monocrystalline modules according to [5] |

Sn |

2.8080 |

||

Ag |

0.7182 |

||

Mg |

0.2889 |

||

Cd |

0.0329 |

||

Te |

0.0254 |

||

In |

0.0243 |

||

Ni |

0.0059 |

||

Ga |

0.0005 |

||

Small wind turbine |

Cu |

8.1000 |

adapted from metal composition to wind turbines from [5] |

Al |

2.5200 |

||

Fe |

0.5160 |

||

Ni |

0.3330 |

||

Nd |

0.1828 |

||

Dy |

0.0146 |

||

Batteries |

Fe |

11.5200 |

[28] |

P |

5.7600 |

||

Li |

1.4400 |

||

Fuel cell |

Zr |

0.2800 |

[29] |

Ni |

0.0800 |

||

Y |

0.0800 |

||

Pt |

0.0028 |

||

Electrolyzer |

Ti |

1.5840 |

[30] |

Al |

0.0810 |

||

Ir |

0.0023 |

||

Pt |

0.0015 |

It must be noted that except for iron, all metals included are considered critical or strategic by the European Commission [7].

From the metallic composition of each component and using the thermodynamic rarity values of each metal, the criticality of each component and the contribution of each metal to that value is calculated. Table 4 compares the contribution of each metal to the mass and the thermodynamic rarity of each component.

Comparison between the contribution of the mass and the thermodynamic rarity of each metal

Component |

Metal |

Mass (kg) |

Mass (%) |

Thermodynamic Rarity (MJ) |

Thermodynamic Rarity (%) |

|---|---|---|---|---|---|

Self-supporting structure |

Fe |

1,930.2064 |

73.00% |

61,766.6058 |

23.46% |

Cr |

423.0589 |

16.00% |

17,303.1108 |

6.57% |

|

Mn |

52.8824 |

2.00% |

3.860.4129 |

1.47% |

|

Ni |

237.9707 |

9.00% |

180,381.7572 |

68.50% |

|

Internal partitions |

Fe |

2,746.1489 |

97.80% |

87,876.7645 |

87.29% |

Mn |

53.3505 |

1.90% |

3,894.5895 |

3.87% |

|

Mo |

8.4238 |

0.30% |

8,895.5007 |

8.84% |

|

Solar PV installation |

Cu |

22.5585 |

85.25% |

7,859.3814 |

8.12% |

Sn |

2.8080 |

10.61% |

1,271.8836 |

1.31% |

|

Ag |

0.7182 |

2.71% |

6,418.5534 |

6.63% |

|

Mg |

0.2889 |

1.09% |

42.1014 |

0.04% |

|

Cd |

0.0329 |

0.12% |

212.1468 |

0.22% |

|

Te |

0.0254 |

0.10% |

71,701.1395 |

74.10% |

|

In |

0.0243 |

0.09% |

8,843.2074 |

9.14% |

|

Ni |

0.0059 |

0.02% |

4.5025 |

0.00% |

|

Ga |

0.0005 |

0.00% |

407.6071 |

0.42% |

|

Small wind turbine |

Cu |

8.1000 |

69.43% |

2,822.0400 |

57.72% |

Al |

2.5200 |

21.60% |

1,665.7200 |

34.07% |

|

Fe |

0.5160 |

4.42% |

16.5120 |

0.34% |

|

Ni |

0.3330 |

2.85% |

252.4140 |

5.16% |

|

Nd |

0.1828 |

1.57% |

122.4492 |

2.50% |

|

Dy |

0.0146 |

0.12% |

9.7686 |

0.20% |

|

Batteries |

Fe |

11.5200 |

61.54% |

368.6400 |

20.72% |

P |

5.7600 |

30.77% |

2.0160 |

0.11% |

|

Li |

1.4400 |

7.69% |

1,408.3200 |

79.16% |

|

Fuel cell |

Zr |

0.2800 |

63.23% |

567.2604 |

6.47% |

Ni |

0.0800 |

18.07% |

60.6400 |

0.69% |

|

Y |

0.0800 |

18.07% |

108.5600 |

1.24% |

|

Pt |

0.0028 |

0.63% |

8,036.0367 |

91.60% |

|

Electrolyzer |

Ti |

1.5840 |

94.92% |

321.7421 |

2.89% |

Al |

0.0810 |

4.85% |

53.5410 |

0.48% |

|

Ir |

0.0023 |

0.13% |

6,457.5295 |

57.98% |

|

Pt |

0.0015 |

0.09% |

4,305.0196 |

38.65% |

In the case of the self-supporting structure, it can be seen that although Fe contributes 73% of the mass in terms of thermodynamic rarity, the most critical metal is Ni with a contribution of 68.5%. In the internal partitions, it is also significant to analyse how Mo, whose contribution to the mass is only 0.3 %, accounts for 8.84% of the Rarity.

From the perspective of energy generation systems, it is worth noting that in the case of PV panels, despite being a metal with a very low mass contribution (0.1%), Te accounts for 74.10% of the Rarity.

Regarding the battery, it is also remarkable that the Li accounts for 79.16% of the Rarity, although its mass contribution is only 7.69 %.

Finally, the high criticality of platinum group metals in hydrogen systems has been proven. In the fuel cell case, Pt accounts for 91.6 % of the Rarity, while in the case of electrolysis, Ir and Pt account for 96.65 %.

To have an overview of the criticality of each component analysed, Table 5 is made. It shows the value of the thermodynamic rarity of each one of them and the contribution in percentage terms to the total value.

Comparison between the contribution to the total thermodynamic modulus rarity of each of the studied components

Component |

Thermodynamic Rarity (MJ) |

Thermodynamic Rarity (%) |

|---|---|---|

Self-supporting structure |

263,311.89 |

54.03% |

Internal partitions |

100,666.85 |

20.66% |

Solar PV installation |

96,760.52 |

19.86% |

Small wind turbine |

4,888.90 |

1.00% |

Batteries |

1,778.98 |

0.37% |

Fuel cell |

8,772.50 |

1.80% |

Electrolyzer |

11,137.83 |

2.29% |

Total |

487,317.4735 |

100.00% |

It is observed that the most critical component is the external enclosures. In this regard, it is important to note that they are made of stainless steel to withstand extreme weather conditions, which is why they are high demand for Ni. On the other hand, it is significant that the solar installation contributes 19.86% to thermodynamic rarity, a value resulting from its demand for metals with high thermodynamic rarity, such as Te or In. Finally, even though H2 generation and usage systems require metals with high thermodynamic rarity, such as Pt or Ir, the small quantities demanded mean that the contribution of these systems to the entire habitable module is very low (1.8% and 2.29% for the fuel cell and the electrolyser, respectively).

Finally, a comparison is made between the final value of the analysed systems' thermodynamic rarity and the module's estimated energy consumption. In this regard, it is worth noting that the module is built to Passive House standards, meaning its maximum annual energy consumption is 120 kWh/year [31]. Considering the total area of the module (71 m²) and comparing it to the thermodynamic rarity (135,365 kWh), it can be stated that at least 15 years of operation are needed for the module's energy consumption to exceed the thermodynamic rarity of the studied components.

Based on the obtained results, the following eco-design recommendations can be formulated for future units:

In terms of construction materials, Ni (Nickel) has a very high impact on rarity. This is due to the use of stainless steel to operate in adverse climatic environments. However, it is recommended that for less demanding locations of the module, painted steel should be used instead. When comparing the stainless-steel panel with the painted steel panel, it is observed that the former has a thermodynamic rarity value of 99.55 MJ/kg, while the latter is 35.85 MJ/kg.

Regarding the use of batteries, the use of LiFePO4 batteries ensures that their impact on the overall rarity is not very significant. This is highly important because if other types of batteries, such as NMC333 (0.10 kg/kWh Li; 0.40 kg/kWh Ni; 0.30 kg/kWh Mn; and 0.40 kg/kWh Co), had been used, the thermodynamic rarity value of the batteries would have multiplied by 39.

If battery storage system is compared with H2 production and use system, conclusions can also be drawn. In this case the module is equipped with a 10.7 kg H2 storage system at different pressure levels. On the other hand, it has four LiFePO4 batteries with a total capacity of 14.4 kWh. Considering a fuel cell efficiency of 60 % it can be stated that in the H2 system has a storage capacity of 214 kWh compared to the 14.4 kWh of the batteries. If we compare the Rarity per unit of stored energy for each system, we have that in the case of LiFePO4 batteries there are 123.4 MJ/kWh compared to 93 MJ/kWh for the H2 system. In this case and excluding from the study the storage system, which is made of carbon fiber, it can be affirmed that from the point of view of resources it is more efficient to store in the form of H2.

In terms of material efficiency, solar PV has a rarity of 17,918 MJ/kW, while small-scale wind power has 1,628 MJ/kW. This represents an 11 times greater impact per unit of power. It is recommended to use wind energy whenever there is sufficient wind resource. However, the study should be expanded to consider the productivity of each technology at a given location to assess which is more cost-effective in terms of resource efficiency. In this regard, it is also recommended to evaluate other photovoltaic technologies, such as amorphous silicon, to determine if they offer an improvement over crystalline silicon. On the other hand, and from the perspective of oversizing the power generation systems, it is recommended that in case of doing so, the wind part should be oversized.

The thermodynamic rarity assessment applied to the ZEROENERGYMOD module offers new insights into material efficiency strategies for modular, energy-self-sufficient construction. The results confirm that the structural frame and internal partitions are the primary contributors to system-level rarity, driven largely by nickel content in stainless steel.

In renewable generation subsystems, our finding of higher rarity intensity for the photovoltaic array compared with the small wind turbine is coherent with CRM-focused studies that identify Te, In, and Ag in PV metallisation as persistent criticality drivers, while wind systems concentrate their rarity in copper, aluminium, and rare-earth magnets. Where wind resources are favourable, prioritising small-scale wind generation can improve resource efficiency; for PV, the most effective levers lie in silver-thrift strategies, substitution of critical semiconductors, and improved end-of-life recovery ‒ measures also identified in recent technology-specific eco-innovation reviews.

For storage technologies, the case-specific outcome that compressed hydrogen exhibits lower rarity per kWh than LiFePO4 batteries aligns with CRM analyses that note the high mass fractions of Li and, in some chemistries, Ni and Co in batteries, versus the low PGM loadings in fuel cells and electrolysers.

Several limitations of the present study should be acknowledged. The Thermodynamic Rarity indicator does not address toxicity, socio-economic risks, or carbon emissions, and should complement, rather than replace, LCA or social-LCA approaches. Results are sensitive to product-specific parameters such as alloy composition, catalyst loading, or coating thickness, and the rarity values used are static, potentially decreasing over time as refining efficiencies improve. Non-metallic materials were excluded from calculations, which may under-estimate the benefits of substitution strategies involving composites or polymers.

The dependence of new technologies on critical materials is evident. The exponential growth of renewable technologies, electric mobility, digitalisation or hydrogen is increasing the demand on certain materials.

In this situation, it is fundamental that the criticality of the materials used is analysed in detail in the construction of new products. The environmental impact of a product can be significantly mitigated if its design and the materials used are carefully studied during the design phase. In this sense, it has been demonstrated that applying the concept of thermodynamic rarity has effectively identified the most critical components of the habitable module and the metals responsible.

This work applied, for the first time, a thermodynamic rarity-based assessment to a container-based, energy-self-sufficient habitable module designed for defence applications. Analysis of seven subsystems revealed that the structural frame and internal partitions accounted for 72% of the total thermodynamic rarity, primarily due to nickel in stainless steel. Photovoltaic modules and hydrogen systems, although representing a smaller mass fraction, showed elevated rarity from tellurium, platinum, and iridium. Under the evaluated conditions, hydrogen storage delivered a higher energy density (MJ/kWh) than lithium iron phosphate batteries.

The results indicate that substituting stainless steel with coated carbon steel where technically feasible, prioritising wind generation over photovoltaics in suitable contexts, and advancing photovoltaic technologies with reduced critical element content could significantly lower reliance on scarce resources without compromising functional performance.

These eco-design strategies contribute directly to United Nations Sustainable Development Goal 7 (Affordable and Clean Energy) by enabling cleaner, autonomous energy systems; to Goal 9 (Industry, Innovation and Infrastructure) by fostering innovative design and materials solutions; and to Goal 12 (Responsible Consumption and Production) by promoting efficient, responsible use of critical materials.

The methodological framework developed here offers a replicable pathway for integrating thermodynamic rarity metrics into sustainable modular construction, applicable to both defence and civilian contexts. Future work should expand rarity databases, refine material substitution options, and conduct pilot implementations with industry partners to accelerate the adoption of these strategies in real-world production.

- ,

Dynamic analysis of the global metals flows and stocks in electricity generation technologies ,J Clean Prod , Vol. 59 , :260-2732013, https://doi.org/10.1016/j.jclepro.2013.07.003. - ,

The omnivorous diet of modern technology ,Resour Conserv Recycl , Vol. 74 , :1-72013, https://doi.org/10.1016/j.resconrec.2013.02.010. - , Critical metals in the path towards the decarbonisation of the EU energy sector: assessing rare metals as supply-chain bottlenecks in low-carbon energy technologies, 2013

- ,

The potential risks from metals bottlenecks to the deployment of Strategic Energy Technologies ,Energy Policy , Vol. 55 , :556-5642013, https://doi.org/10.1016/j.enpol.2012.12.053. - ,

Material bottlenecks in the future development of green technologies ,Renewable and Sustainable Energy Reviews , Vol. 93 , :178-2002018, https://doi.org/10.1016/J.RSER.2018.05.041. - ,

Metals for energy & digital transition in Spain: Demand, recycling and sufficiency alternatives ,Resour Conserv Recycle , Vol. 205 , :1075972024, https://doi.org/10.1016/j.resconrec.2024.107597. - ,

From emissions to resources: mitigating the critical raw material supply chain vulnerability of renewable energy technologies ,Mineral Economics , Vol. 37 , :669-6762024, https://doi.org/10.1007/s13563-024-00425-2 - ,

- , , Towards recycling indicators based on EU flows and raw materials system analysis data: supporting the EU-28 raw materials and circular economy policies through RMIS, 2018

- ,

Strategic mineral resources: Availability and future estimations for the renewable energy sector ,Environ Dev , Vol. 41 , :1006402022, https://doi.org/10.1016/j.envdev.2021.100640. - ,

Assessment of Ecodesign potential in reaching new recycling targets ,Resour Conserv Recycl , Vol. 54 (12), :1128-11342010, https://doi.org/10.1016/j.resconrec.2010.03.006. - ,

Industry attitudes towards ecodesign standards for improved resource efficiency ,J Clean Prod , Vol. 123 , :155-1662016, https://doi.org/10.1016/J.JCLEPRO.2015.12.035. - ,

Ecodesign methods focused on remanufacturing ,J Clean Prod , Vol. 18 (1), :21-312010, https://doi.org/10.1016/J.JCLEPRO.2009.09.005. - ,

From energy efficiency towards resource efficiency within the Ecodesign Directive ,J Clean Prod , Vol. 144 , :358-3742017, https://doi.org/10.1016/J.JCLEPRO.2016.12.144. - ,

EcoDesign and The Ten Golden Rules: generic advice for merging environmental aspects into product development ,J Clean Prod , Vol. 14 (15–16), :1396-14082006, https://doi.org/10.1016/J.JCLEPRO.2005.11.022. - ,

Disassemblability Assessment of Car Parts: Lessons Learned from an Ecodesign Perspective ,Sustainability (Switzerland) , Vol. 16 (6), 2024, https://doi.org/10.3390/su16062311. - ,

Toward Material Efficient Vehicles: Ecodesign Recommendations Based on Metal Sustainability Assessments ,SAE International Journal of Materials and Manufacturing , Vol. 11 (3), :213-2282018, https://doi.org/10.4271/05-11-03-0021 - ,

Eco Breakthroughs: Sustainable Materials Transforming the Future of Our Planet ,Sustainability , Vol. 16 (23, art), :10790, https://doi.org/10.3390/su162310790. - ,

, Thanatia: the destiny of the Earth’s mineral resources: a cradle-to-cradle thermodynamic assessment , 2015, https://doi.org/10.1111/jiec.12426. - ,

- , , Critical raw materials for strategic technologies and sectors in the EU: a foresight study, 2020

- ,

Vehicles and critical raw materials. ,A sustainability assessment using thermodynamic rarity, Industrial Ecology , 2017, https://doi.org/10.1111/jiec.12737. - ,

Decreasing Ore Grades in Global Metallic Mining: A Theoretical Issue or a Global Reality? ,Resources , Vol. 54 , :362016, https://doi.org/10.3390/resources5040036. - ,

Modeling fossil energy demands of primary nonferrous metal production: The case of copper ,Environ Sci Technol , Vol. 47 (24), :13917-139242013, https://doi.org/10.1021/es4030518. - ,

Thermodynamic assessment of raw material use in passenger vehicles, Universidad de Zaragoza ,Zaragoza , 2019 - ,

Vehicles and Critical Raw Materials: A Sustainability Assessment Using Thermodynamic Rarity ,J Ind Ecol , Vol. 22 (5), :1005-10152018, https://doi.org/10.1111/jiec.12737. - ,

Eco-credit system to incentivise the recycling of waste electric and electronic equipment based on a thermodynamic approach ,International Journal of Exergy (IJEX) , Vol. 35 (1), :M2021, https://doi.org/10.1504/IJEX.2021.115090. - ,

- ,

Energy modeling approach to the global energy-mineral nexus: Exploring metal requirements and the well-below 2 °C target with 100 percent renewable energy ,Appl Energy , Vol. 225 , :1158-11752018, https://doi.org/10.1016/j.apenergy.2018.05.047. - ,

Critical and strategic raw materials for electrolysers, fuel cells, metal hydrides and hydrogen separation technologies ,Int J Hydrogen EnergyVol , Vol. 71 , :433-4642024, https://doi.org/10.1016/j.ijhydene.2024.05.096. - ,